Metal Panel Products

Metal facade systems can make buildings look more attractive, but they also serve practical purposes, The metal panels protect the building from weather conditions like rain, wind, and sunlight. They can also help insulate the building, keeping it cooler in the summer and warmer in the winter.

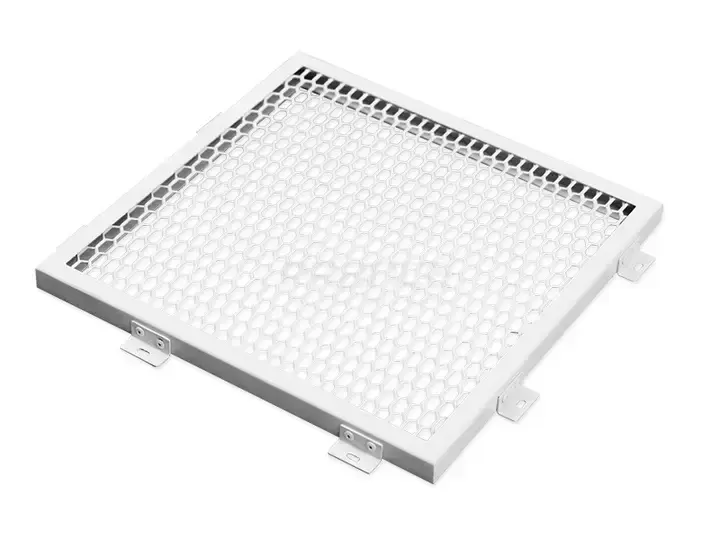

Metal Ceiling Products

Metal interior ceiling systems come in various styles and designs offering versatility and customization options.

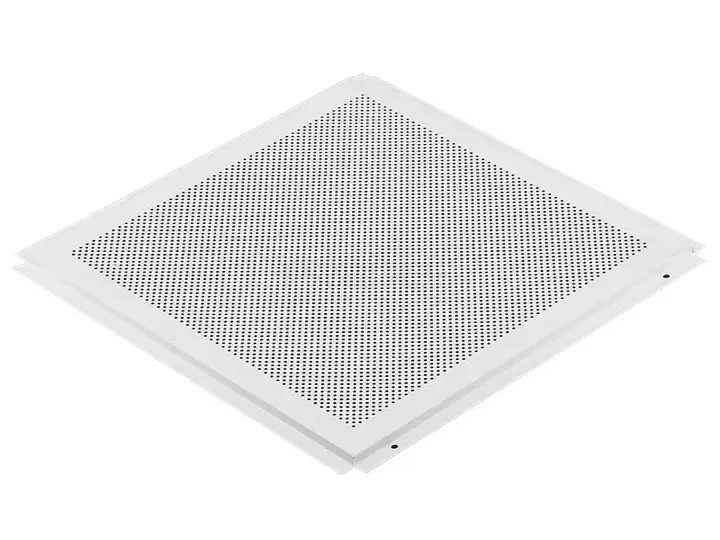

Custom Decorative Metal Panel

Customized metal panel is a type of construction materlal made from metal sheets that can be cut and shaped to ft speclfic proiectrequirements. The advantages of custom metal panels are numerous. First,they offer a modern, sleek look and are avalable in a varlety of finishes and colors, making them sultable for a wide range of architecturaldesigns. They are also durable, long-lasting, and require minimal maintenance. in addition, they can be customized to meet specific projectrequirements.such as size, shape, and perforation pattems.

Custom metal panels have become increasingly popular worldwide due to their aesthetic appeal, durability, and flexibility in desien. They arecommonly used in commerclal nstitutlonal, and residentlal bulldings and are considered a sustainable building material due to thelrrecyclability and energy efficiency. Welcome to inquire about custom aluminum panels price, PRANCE is the best choice of metal panel manufacturer.

Why We Choose Custom Decorative Metal Panel?

Aluminum Alloy Material Performance

| AluminumAlloy Model | Strength | CorrosionResistance | Workability | Weldability | TensileStrength | BendingStrength | Elongation |

| A1100 | Low | Excellent | Excellent | Poor | 110-136 Mpa | 70 Mpa | 3540% |

| A3003 | Medium | Good | Good | Good | 130-180 Mpa | 115 Mpa | 18-25% |

| A5052 | High | Excellent | Good | Poor | 210-260Mpa | 190 Mpa | 12-17% |

| A6061 | Very high | Good | Good | Good | 240-310 Mpa | 210 Mpa | 1623% |

Note: A1100 is an aluminum alloy with a purity of 99.00%, which makes it very soft and ductile. t has excelent workability, flexiblity and formabilityand is easy to weld, but it has low strength compared to other alloys. This makes it sutable for metal celling and wall applications.

A3003 is an aluminum-maneanese alloy with good corosion resistance. moderate streneth. and excellent workabilty. It is commonly used indecorative metal celing and wal industry because of its abllity to be easily formed into varlous shapes and its good corrosion resistanceproperties

A5052 is an aluminum-manganese alloy with higher strength than A3003, and is commonly used in applications where higher strength anddurablty are required, such as in the marine and aviation industries. It also has good corrosion resistance and is often used with anodizingfinish panel.

A6063 is a heat-treatable aluminum alloy with good extrusion propertles, which makes it a popular choice for architectural applications such aswindow frames. door frames and curtain walls. Although it has ower strength, t is stil suitable for applicatlons where strength is not theprimary concemn.For more comparison between material or any questions, please contact with PRANCE colleague.